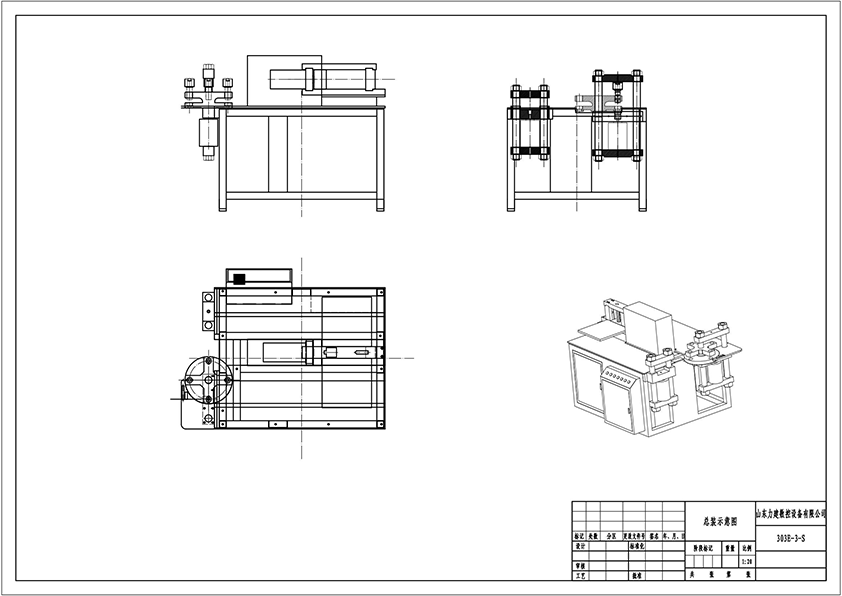

1.Introduction

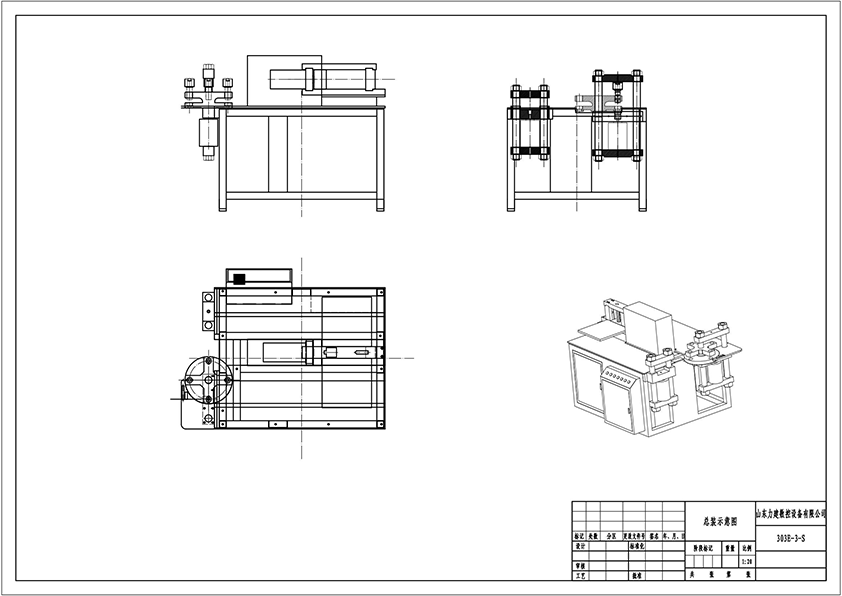

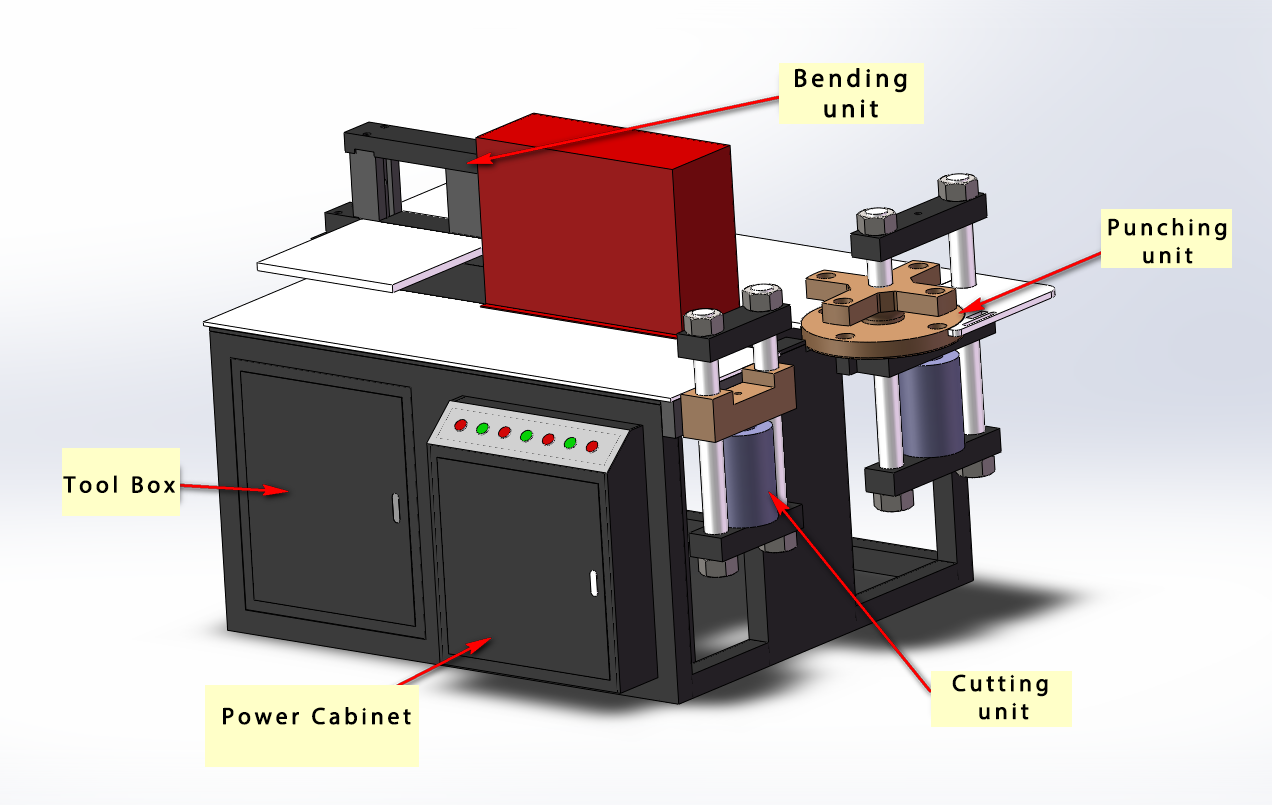

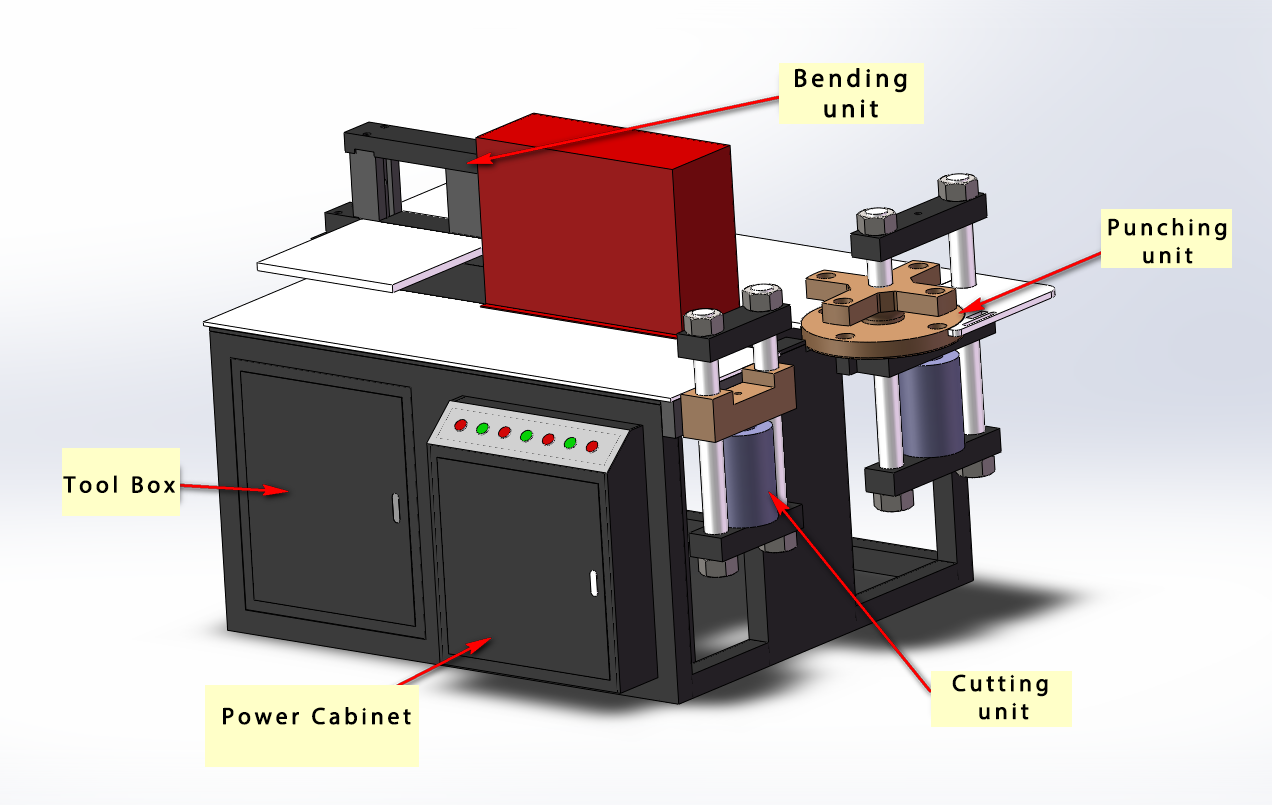

The machine is equipped with punching cutting bending three units, the three units can work at the same time, and will not influence each other. The punching unit is turret structure, the bending unit is closed on the top, the bending angle is with storage function. The main function is processing different types of copper (brass) aluminum bus bar. When it is working, workers just need to choose the unit, then machine will cutting and punching (holes,long holes square holes special holes), horizontal bending, vertical bending, embossing, leveling , twisting, and ect.2.Main Characteristic1.SIEMENS 40 PLC control system from German, which is with Automatic shutdown function, and can control the down time of cutting unit and punching unit, it is more stable and reliable than traditional relays.

2.Punching unit is with nodular-cast-ironed and turret typed turntable with 4/6/8 molds holes, which is a whole one, so that the holes for molds (the molds is processed by our processing center) with higher precision and the clearance of the molds and turntable is 0.00-0.03mm, improving the concentricity, then the life of molds can be longer and need not change the molds so frequently.

3.By added punching position, the machine can locate x axis and y axis mechanical double direction location. That makes workers don’t need cross lines and make punching marks, then improving the operating efficiency and accuracy of punching.

4.Cutting unit is with double upright pillars and double blades cutting structure (Patent NO.ZL201120262802.1) the above blade and below blade are installed vertically parallelly, make sure the cut smooth, no waste, no deformation for longtime used.

5.Bending unit is with closed bending, output point and force bearing force are connecting with beam of 50mm thickness, the mechanical strength is stronger than those open bending.

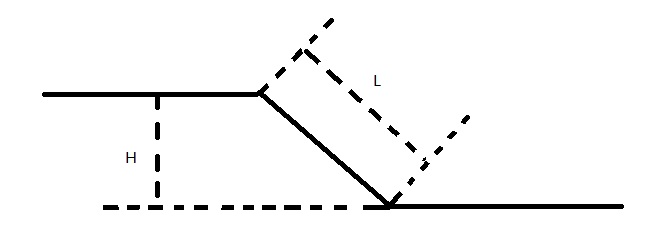

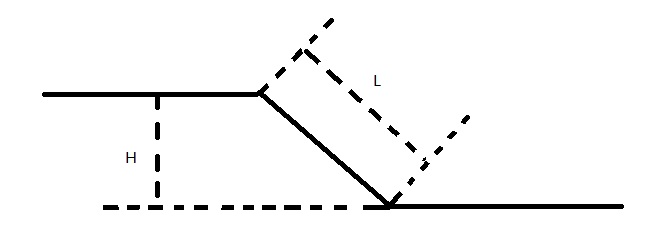

6.Bending angel is controlled by numerical control system. Z bending can be processed through enter H (vertical height of above and below planes) and L (length of Hypotenuse) (it can calculate the angel that needed itself). When it is working , workers just need enter the angel and the thickness for the busbar that needed then the machine can processing the parts conveniently and fast. And the machine is with storage function and error compensation.

7.Bending unit can processing U bending. The minimum distance is 40mm.

8.Hydraulic oil tank is welded by 3mm thickness steel plate, and with phosphating, making the hydraulic oil can be used longer and will not be deterioration.

9.The machine offers the oil one to one, three cylinders/three pumps, not influence each other.

10.Cylinder oil tubes are with international A type connection, durable and easy to repair.

11.The machine is with casters, easy to move.

Main parts:

1 Main Motor Juliweite 3

2 Hydraulic Oil Cylinder LIJIAN (MADE IN TAIWAN, China) 3

3 Electromagnetic reversing valve FENGYI 3

4 Electromagnetic relief valve FENGYI 3

5 AC contactor SIEMENS 3

6 Thermal relay SIEMENS 3

7 PLC SIEMENS 1

8 Encoder GUANGYU 1

9 Touch screen PanelMaster 1Random Annex:Punching molds × 8(Φ7、Φ9、Φ11、Φ13、Φ17、Φ11×15、Φ13×17、Φ17×21)

Cutter × 1

Horizontal bending molds × 3

Embossing molds × 1

Random repair tool × 1

Standby seal ring × 1

Foot switch × 3

5.Parameter:

Parameter Value

Nominal Pressure 350 kN

Maximum Cutting Size 12 mm × 160 mm

Punching Size Φ4.3 mm - Φ25 mm

Maximum Horizontal Bending Size 12 mm × 160 mm

Maximum Vertical Bending Size 12 mm × 120 mm

Workbench Maximum Size First: 1500 mm × 1200 mm

Second: 940 mm × 420 mm

Machine Size 1750 mm × 1350 mm × 1500 mm

Machine Weight 1390 kg

Lijian DGWMX303E-3-S CNC busbar machine: High Precision and Smart Automation for Modern Busbar Processing

Introduction

The Lijian DGWMX303E-3-S CNC Busbar Machine is a compact, efficient, and intelligent solution for busbar fabrication. Specifically designed for small to medium-sized power distribution processing tasks, this three-station CNC machine integrates shearing, punching, and bending functions into one fully automated unit. It is ideal for manufacturers of switchgear, control cabinets, and power panels that require consistent, high-precision busbar processing.

Built on Lijian’s robust engineering philosophy, the DGWMX303E-3-S provides unmatched productivity, energy efficiency, and intelligent control for modern electrical manufacturing lines.

1. Product Overview

The DGWMX303E-3-S belongs to the advanced DGWMX-series, which stands for high-end, modular busbar solutions. This model is engineered with high-grade steel frame construction, integrated hydraulic systems, and precision servo feeding mechanisms. It is optimized for high-volume and high-accuracy processing of copper and aluminum busbars.

Key Technical Parameters

| Parameter | Value |

|---|

| Max Busbar Width | ≤ 125 mm |

| Max Busbar Thickness | ≤ 10 mm |

| Shearing Force | 300 kN |

| Punching Force | 300 kN |

| Bending Force | 300 kN |

| Max Bending Angle | 0°–180° |

| Feeding Accuracy | ±0.15 mm |

| Control System | CNC + PLC |

| Voltage | 3-Phase 380V / 50Hz |

| Total Power | ~18–22 kW |

2. Integrated Processing Modules

2.1 CNC Shearing Module

Equipped with a hardened cutting blade and powerful hydraulic drive, the shearing unit cuts copper and aluminum busbars with high edge quality. Precision feeding ensures optimal material utilization and clean, burr-free ends.

2.2 CNC Punching Module

This module allows flexible hole patterns using quick-change die sets. It supports multiple shapes including round, square, oval, and customized designs, making it suitable for both standard and specialized busbar terminals.

2.3 CNC Bending Module

The bending station delivers fully programmable angular bends up to 180°, allowing V-bends, U-bends, and offset configurations. With closed-loop servo control, it ensures exact bending angles with no rebound.

3. Intelligent CNC Control System

The DGWMX303E-3-S features an advanced touchscreen CNC system with the following advantages:

Graphical Interface: Users can program operations via intuitive diagrams, eliminating the need for G-code expertise.

Program Storage: Save and retrieve up to 1,000 operation programs for fast switching between product types.

Error Detection: Real-time sensor feedback prevents crashes and alerts operators to errors instantly.

USB Import/Export: Transfer operation files for batch production or backup.

Language Support: Multilingual operation (including English, Spanish, Chinese, etc.)

4. Intelligent Feeding and Clamping

The servo-controlled feeding system allows fast, precise positioning between stations. High-friction rollers combined with automatic clamps ensure the busbar remains secure during transfer. This system minimizes misalignment and eliminates manual repositioning, improving overall efficiency and operator safety.

5. Structural and Functional Highlights

5.1 Compact Frame

The entire machine is built into a single, rugged frame with vibration-damping support, ideal for space-constrained workshops.

5.2 Hydraulic Efficiency

Advanced hydraulic circuitry reduces idle energy consumption and improves response times for faster cycle speeds.

5.3 Noise and Vibration Reduction

High-precision machining, balanced hydraulic pumps, and servo motors work together to ensure quiet, stable operation — meeting modern environmental and workplace noise standards.

5.4 Tool-Free Maintenance

Key modules like die holders and clamps are designed for quick release, simplifying routine maintenance and tooling changes.

6. Application Fields

The Lijian DGWMX303E-3-S is widely used in the following sectors:

Power Distribution Equipment Manufacturing

Switchgear Assembly

Control Panel Production

Renewable Energy and EV Infrastructure

Industrial Automation Systems

Construction and Engineering Projects

Its flexibility and precision make it suitable for both high-volume batch production and custom electrical component fabrication.

7. Advantages over Traditional Busbar Machines

| Feature | Traditional Model | DGWMX303E-3-S |

|---|

| Processing Speed | Medium | High |

| Automation | Semi-automatic | Fully Automatic |

| Control Accuracy | Manual adjustment | ±0.15 mm with servo control |

| Operator Training | Skilled required | Beginner-friendly touchscreen |

| Energy Efficiency | High consumption | Energy-saving hydraulic system |

| Setup Time | Long | Fast (tool-free changes) |

8. Industry 4.0 Compatibility

To meet smart manufacturing demands, the DGWMX303E-3-S supports:

MES System Integration: Upload production data in real time

IoT Connectivity: Monitor performance remotely

Cloud-Based Maintenance Alerts: Predictive fault detection

Barcode Scanning Compatibility: For quick program switching

9. Safety Features

Operator safety is prioritized through:

Fully enclosed processing area

Safety light curtains and emergency stop buttons

Hydraulic overload protection

Anti-pinch servo feeding design

Real-time system monitoring with alerts

10. Lijian Technical Support & Services

Lijian offers a full suite of support to ensure your investment operates at peak performance:

On-site Installation & Commissioning

Operator Training Sessions

Spare Parts Guarantee

Remote Troubleshooting & Upgrades

Lifetime Technical Support Hotline

Their experienced engineers are always ready to assist globally with prompt response and expert guidance.

11. Customer Case Studies

Case A: Panel Manufacturer in Southeast Asia

Increased busbar output by 70% and reduced labor cost by 40% after switching to DGWMX303E-3-S.

Case B: OEM Electrical Assembly in Europe

Reported “zero defects” for three consecutive months in automated punching and bending operations.

Conclusion

The Lijian DGWMX303E-3-S CNC Busbar Machine represents the next generation of compact, high-efficiency busbar processing. Engineered for flexibility, speed, and accuracy, it is the ideal solution for modern power distribution equipment manufacturers who need reliable, scalable production tools.

From precise processing and intelligent automation to safety and smart factory readiness, the DGWMX303E-3-S delivers powerful performance in a small footprint.