1.Introduction

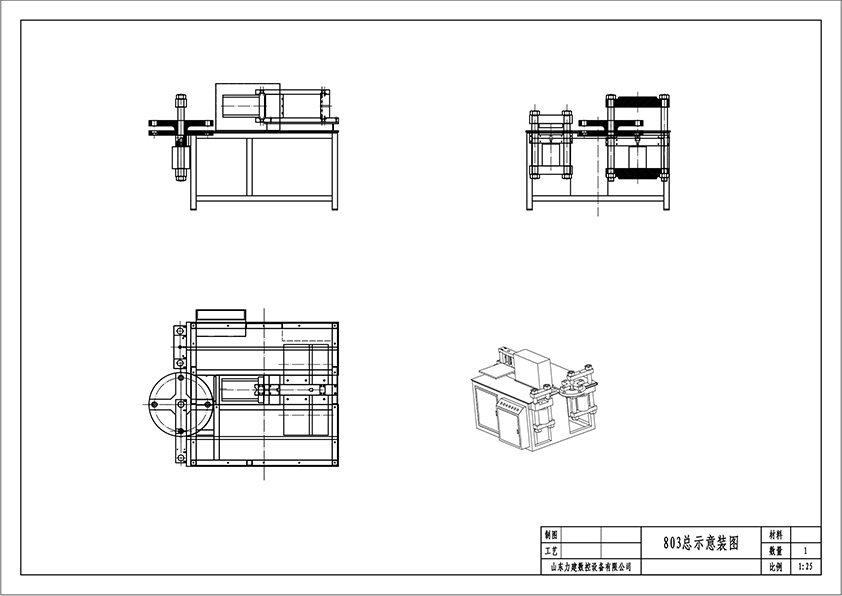

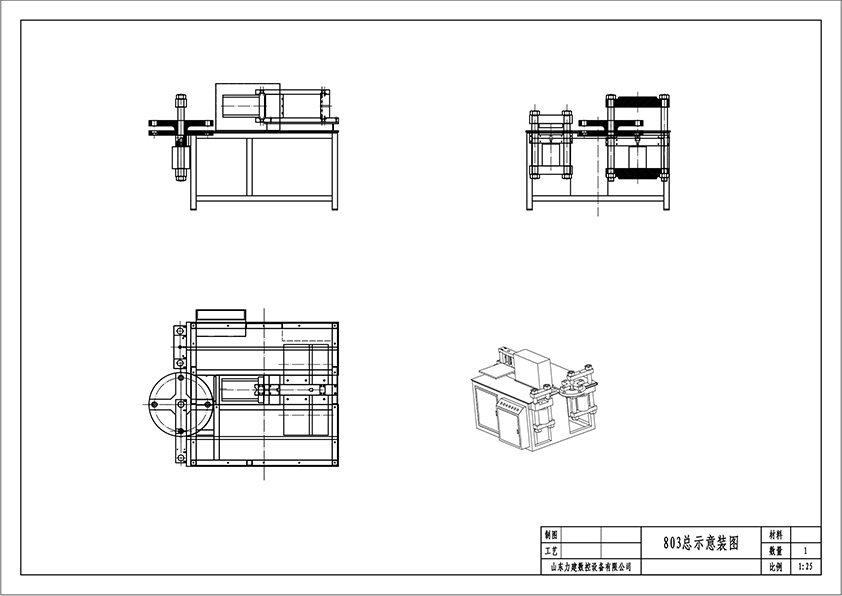

The machine is equipped with punching cutting bending three units, the three units can work at the same time, and will not influence each other. The punching unit is turret structure, the bending unit is closed on the top, the bending angle is with storage function. The main function is processing different types of copper (brass) aluminum bus bar. When it is working, workers just need to choose the unit, then machine will cutting and punching (holes,long holes square holes special holes), horizontal bending, vertical bending, embossing, leveling , twisting, and ect.

2.Main Characteristic:

1.★SIEMENS 40 PLC control system from German, which is with Automatic shutdown function, and can control the down time of cutting unit and punching unit, it is more stable and reliable than traditional relays.

2.Punching unit is with nodular-cast-ironed and turret typed turntable with 4/6/8 molds holes, which is a whole one, so that the holes for molds (the molds is processed by our processing center) with higher precision and the clearance of the molds and turntable is 0.00-0.03mm, improving the concentricity, then the life of molds can be longer and need not change the molds so frequently.

3.By added punching position, the machine can locate x axis and y axis mechanical double direction location. That makes workers don’t need cross lines and make punching marks, then improving the operating efficiency and accuracy of punching.

4.Cutting unit is with double upright pillars and double blades cutting structure (Patent NO.ZL201120262802.1) the above blade and below blade are installed vertically parallelly, make sure the cut smooth, no waste, no deformation for longtime used.

5.Bending unit is with closed bending, output point and force bearing force are connecting with beam of 50mm thickness, the mechanical strength is stronger than those open bending.

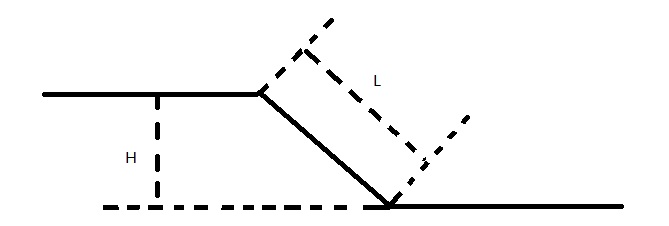

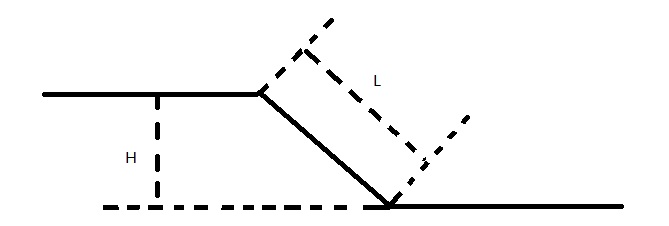

6.Bending angel is controlled by numerical control system. Z bending can be processed through enter H (vertical height of above and below planes) and L (length of Hypotenuse) (it can calculate the angel that needed itself). When it is working , workers just need enter the angel and the thickness for the busbar that needed then the machine can processing the parts conveniently and fast. And the machine is with storage function and error compensation.

7.Bending unit can processing U bending. The minimum distance is 40mm.

8.Hydraulic oil tank is welded by 3mm thickness steel plate, and with phosphating, making the hydraulic oil can be used longer and will not be deterioration.

9.The machine offers the oil one to one, three cylinders/three pumps, not influence each other.

10.Cylinder oil tubes are with international A type connection, durable and easy to repair.

11.The machine is with casters, easy to move.

3.Main parts:

| 1 | Main Motor | Juliweite | 3 |

| 2 | Hydraulic Oil Cylinder | LIJIAN (MADE IN TAIWAN, China) | 3 |

| 3 | Electromagnetic reversing valve | FENGYI | 3 |

| 4 | Electromagnetic relief valve | FENGYI | 3 |

| 5 | AC contactor | SIEMENS | 3 |

| 6 | Thermal relay | SIEMENS | 3 |

| 7 | PLC | SIEMENS | 1 |

| 8 | Encoder | GUANGYU | 1 |

| 9 | Touch screen | PanelMaster | 1 |

4.Random Annex:

Punching molds × 8(Φ7、Φ9、Φ11、Φ13、Φ17、Φ11×15、Φ13×17、Φ17×21)

Cutter × 1

Horizontal bending molds × 3

Embossing molds × 1

Random repair tool × 1

Standby seal ring × 1

Foot switch × 3

5.Parameter:

| Parameter | Value |

| Nominal Pressure | 800 kN |

| Maximum Cutting Size | 16 mm × 260 mm |

| Punching Size | Φ4.3 mm - Φ36 mm |

| Maximum Horizontal Bending Size | 16 mm × 260 mm |

| Maximum Vertical Bending Size | 16 mm × 260 mm |

| Workbench Maximum Size | First: 1770 mm × 1600 mm |

| Second: 1120 mm × 450 mm |

| Machine Size | 2150 mm × 1750 mm × 1500 mm |

| Machine Weight | 2280 kg |

Lijian busbar machine DGWMX803E-3-S: High-Performance CNC Busbar Processing Center for Modern Power Systems

Introduction

The Lijian DGWMX803E-3-S Busbar Machine is a top-tier CNC busbar processing center designed to meet the evolving demands of electrical manufacturing industries. Built with precision automation, multi-functional stations, and intelligent control systems, this all-in-one machine provides comprehensive processing capabilities for copper and aluminum busbars. It is engineered for enterprises seeking maximum efficiency, accuracy, and flexibility in large-scale or high-mix low-volume production environments.

1. Product Overview

The Lijian DGWMX803E-3-S integrates shearing, punching, and bending into a single CNC-controlled unit. It eliminates the need for separate machines, streamlines workflow, and minimizes handling time. With a robust frame, high-torque servo motors, and PLC automation, the machine ensures long-term stability and repeatable precision.

Technical Specifications:

Model: DGWMX803E-3-S

Busbar Size: Width ≤ 160mm, Thickness ≤ 15mm

Functions: Shearing, Punching, Bending

Operation Mode: CNC Automatic

Control System: Touchscreen HMI + PLC

Processing Accuracy: ±0.15mm

Production Capacity: Up to 8–12 workpieces/min (depending on complexity)

Power Supply: 380V, 50Hz, 3-phase

Hydraulic Pressure: Max. 31.5MPa

Dimensions: Customized according to configuration

2. Core Functional Modules

2.1 CNC Shearing Station

Equipped with a high-strength blade and servo-positioning guide system, the shearing station delivers clean, burr-free cuts. Programmable cutting lengths reduce manual setup time and material waste.

2.2 Punching Station

The punching module features a high-speed hydraulic cylinder with interchangeable dies. It supports various hole shapes (round, oval, square) and pattern combinations, ideal for complex control cabinet or transformer designs.

2.3 Bending Station

Utilizing a multi-axis servo-controlled arm, the bending station allows for precise 0°–180° bending. Programmable memory ensures consistent performance even on intricate multi-bend shapes.

2.4 Auto Material Feeding

The DGWMX803E-3-S includes a roller-driven automatic feeding system with servo motor tracking. Material is positioned with millimeter accuracy, ensuring smooth transitions between stations.

3. Advanced CNC Control System

The machine is operated via a large, industrial-grade touchscreen interface with real-time monitoring, diagnostic display, and editable process libraries. Its features include:

Graphical programming interface

Workpiece simulation previews

Error code feedback & troubleshooting guide

Multi-language support

The system allows offline programming and USB data import for enhanced flexibility.

4. Intelligent Workflow Design

4.1 Modular Processing Sequence

All stations operate independently and can be re-sequenced via software depending on the production requirements. This modularity maximizes uptime and allows for multiple product types without mechanical retooling.

4.2 Workflow Efficiency

By integrating three functions in one platform, DGWMX803E-3-S significantly reduces:

The result is a leaner, more agile manufacturing process.

5. Applications

This machine is ideal for manufacturers in the following industries:

High-voltage and low-voltage switchgear manufacturing

Power distribution cabinet production

Electric panel board fabrication

Railway signal systems and metro power equipment

Wind and solar power infrastructure

Whether for standard or custom production, the DGWMX803E-3-S adapts to various industrial needs with ease.

6. Key Benefits and Competitive Advantages

6.1 One-Stop Busbar Processing

Combining shearing, punching, and bending in one station minimizes layout complexity and frees up floor space.

6.2 Precision and Repeatability

Advanced positioning systems and feedback loops ensure consistent results. Bending precision of ±0.3° and hole punching accuracy of ±0.15mm make it ideal for mission-critical applications.

6.3 Scalable Production

The machine easily switches between batch production and custom orders, supporting high-mix low-volume (HMLV) or mass production with equal efficiency.

6.4 Reduced Operating Costs

Lower scrap rates, fewer operators, and fast cycle times reduce long-term costs while maximizing ROI.

6.5 Durable and Low Maintenance

Equipped with a wear-resistant hydraulic system, industrial-grade cylinders, and heat-treated mechanical components, the DGWMX803E-3-S ensures stability and longevity with minimal service intervention.

7. Safety and Environmental Features

Enclosed operation zones to protect operators from hydraulic and mechanical hazards

CE-compliant emergency stop systems

Oil filtration and recovery systems

Noise suppression housing

Energy-efficient servo motor systems

8. Integration with Smart Manufacturing

The Lijian DGWMX803E-3-S is ready for Industry 4.0 with the following features:

IoT-enabled control module

Remote firmware updates and diagnostics

MES/ERP system integration capability

Production analytics dashboard

Digital quality tracking and report generation

These features allow users to move towards fully automated, intelligent factories.

9. Technical Support & Service

Lijian provides comprehensive after-sales support:

Installation and commissioning

Operator and technician training

Online and on-site technical support

Spare parts supply and software upgrades

Lifetime consultation on application optimization

10. Real-World User Feedback

Here are some real-world insights from users of DGWMX803E-3-S:

“It reduced our processing time by 60% with better accuracy than three separate machines.”

“Reliable for 2-shift daily production. We’ve processed over 50,000 busbars in 8 months.”

“Programming is intuitive and fast to learn. It made batch orders far easier.”

Conclusion

The Lijian DGWMX803E-3-S CNC Busbar Machine is an ideal solution for manufacturers seeking to improve efficiency, quality, and production flexibility. With its robust performance, advanced automation, and integrated functions, it is well-suited for the future of electrical system manufacturing.

For manufacturers looking to scale production, reduce downtime, and stay ahead of industry standards, the DGWMX803E-3-S offers long-term value and competitive performance.

RELATED

RELATED

RELATED

RELATED